charpy impact test notch|charpy v notch testing requirements : purchasers The Charpy impact test, also referred to as Charpy v-notch test, is a materials testing method used to determine the impact strength of materials using a pendulum impact tester. 22 de abr. de 2023 · Resultados da Lotomania 2458, 22/04/2023, 7 Milhões. Veja resultado, números sorteados e premiados do concurso 2458 da Lotomania do dia .

{plog:ftitle_list}

11 de abr. de 2022 · Fluxo de simulação simplificado: saiba quanto vai receber em 5 passos. Quer saber quanto vai receber em cada compra? Com apenas 5 passos isso é possível. Você coloca o preço de venda, atualiza os filtros disponíveis e pronto, já tem o valor atualizado ali mesmo. Confira o passo a passo: No app, no menu inferior, acesse .

charpy v notch toughness

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

tablet thickness and diameter test

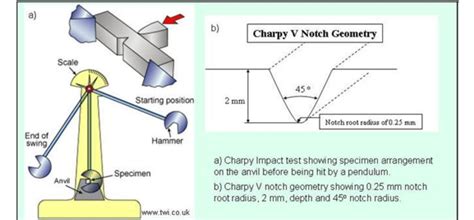

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .The Charpy impact test, also referred to as Charpy v-notch test, is a materials testing method used to determine the impact strength of materials using a pendulum impact tester. The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture.The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .

A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of .

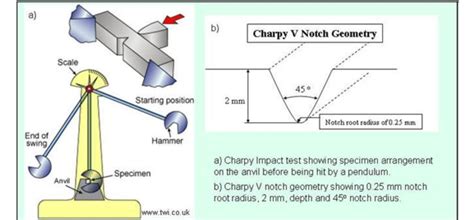

To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.

This puts the side with the notch into tension, causing an initiation of fracture from the notch. Figure 2 Charpy Test Specimen under Load. The most commonly used specimen, the Charpy V-notch (CVN), is 10 × 10 × 55 mm .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018) : Plastics — Determination of Izod pendulum impact resistance ISO 180:2019 : Plastics — Determination of Izod impact strength What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. See Figure 1 below:

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . There are two main forms of impact test, the Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed. The amount of . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the . 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide . This article will discuss the benefits of the method and how to Charpy test steel and other metallic products. Charpy Test Method. The setup needed for Charpy testing consists of a rectangular beam of metal to be .

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).For standardized testing of fracture toughness by the Charpy impact method, specimen and notch dimensions are most often taken from American standard ASTM E23, or British standard BS EN ISO 148-1:2009. For all notch types, a key parameter in governing stress concentration and failure in notched materials is the notch tip curvature or radius. [1]

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type . In the Charpy test, the specimen has a notch cut across the middle of one of its faces. It is placed as a simply supported beam and the

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .A Charpy impact test, also known as the Charpy V-notch test, is a destructive method designed to measure the amount of energy that a material can absorb as it fractures. Understanding this helps to predict how the material will react to impact loading and is, therefore, an essential determining factor when assessing if your material is suitable .

As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used.

Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch.defined hereafter, a test piece V-notched in the middle and resting on two supports. The energy absorbed is determined. 3. Designations and Units - Designations and their units applicable to this standard are as indicated in Fig. 1 and Table 1. FIG. 1 CHARPY IMPACT TEST (V-NOTCH ) TABLE 1 DESIGNATIONS AND UNITS4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. 7 Recommendations for specifying impact strength requirements in steel specifications.

tablet thickness test

Resultado da 19 de jul. de 2019 · A história do Japão Medieval é geralmente dividida nos seguintes períodos: Período Kamakura (1185-1333) Período Muromachi (1333-1573) Junto com o Período Sengoku (1467-1568) Período Azuchi-Momoyama (1573-1600) Alternativamente, pode ser dividido de acordo .

charpy impact test notch|charpy v notch testing requirements